.STL file = The standard 3d printable 3d model file type. Steps in Detail: 1. The main Enginerdog Logo was created for me by talented animation artist Jesse J Jones, so selected because I love his work. I copied the image and pasted into a Microsoft Paint window so I could make the. Import the STL file model into the 3D printing software that comes with the 3D printer. A window will pop up and ask where the model should be placed. Click on absolute center as this would put the model in the middle of the printing tray.

If you are reading this article that means that you've probably decided to join the community of 3d printing enthusiasts and find out more about 3d printers, or maybe you have already got some experience in it and are ready to try to create your own 3d printer from scratch.

In this article you will find general understanding how 3D printers can be built as well as links to really useful resources where you can find more detailed information with step-by-step description.

Currently there is a big variety of 3d printers in the Internet that already assembled and are ready to print right after you unpack them from a box, of course you also need to buy a 3d printer filament for it. Do not forget that not all 3d printers can use the same filament types, so please read the instruction before you purchase it.

But for some people who love to make something new with their own hands can be more interesting to build their own 3d printer from scratch. Based on our research the 3D printing community is filled with many enthusiastic people so called DIY'ers (Do It Yourself'ers), who are fascinated with building 3d printers literally almost from scratch.

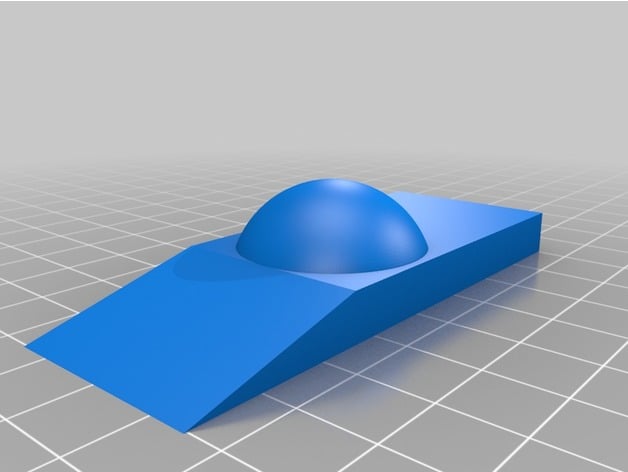

Good example of it is RepRap movement. RepRap is short for a Replicating Rapid-prototyper. In other words it is the self-replicating 3d printer. In fact most of today's top consumer level 3D printers (picture above) are originated in one way or another from RepRap.

You can find a lot of examples on how to build a 3d printer from scratch on RepRap website, but we also want to describe some of more essential steps in order to give an overall understanding of what to expect if you really decide to make your own 3d printer.

The first step is to find and buy 3d printer DIY kit. Kits usually contain most of parts needed to assemble the printer and can be divided into two main types:

Scratch Built 3D Printer – This 3d printer DIY kit is for those who prefer to build thing from scratch, or in other words go to DIY RepRap route. Apart from some essential advantages this approach has also its disadvantages. In theory it can save you some money and since you build it from scratch you will know every nut and bolt in it by the time you can use it and successfully print your first object. Main disadvantage of this method is time. Literally it will take a lot of time to deal with all these hundreds of bolts, wires, belts and much other stuff. In the end you still need to select and purchase or build a controller board, but it depends on your skills level.

Kit Built 3D Printer – This type of kit is good if you want to save some money and at the same time not to deal with all challenges described in the 1st kit type. Many manufactures sell such kits with 'easy-to-assemble' instructions included. I doubt that it will be as easy as assemble a chair from IKEA, so you still have to be mechanically inclined and able to understand basic geometry. Some of such kits contain not all parts and you may need to buy something in addition.

The next step will be to determine the design for your 3D printer. In my humble opinion most of DIY 3D printers have not very breathtaking and futuristic design in comparison with MakerBot and other brands. But it is also a matter of taste, for some people the design is not very important.

Once you have got your 3d print DIY kit and chosen the design you could go ahead and start the most fascinating and time consuming part – build your own 3d printer. Be prepared for sleepless nights and a lot of fun. Maybe you will make up something new and present your findings to RepRap community.

When the hardware part of the 3d printer is ready you also need to add a software component to it. It basically does the following things: allows you to view and alter 3d graphical objects, as well as converts the 3d images into instructions that 3d printer can understand.

Finally you can 3d print your first object! Fl studio computer price. If you do not have anything to print, you can find a big variety of objects on specialized marketplaces such as Shapeways, Thingiverse and others. Before printing make sure that the object you want to 3d print has the right size and fit on the printer frame.

At the end there is a list of some links where you can find more information about how to build your own 3d printer from scratch:

Also watch a video from Ben Heck in which he answers on some 3d printing related questions.

Related Articles:

An STL file is a stereolithography file. This file type is native to the stereolithography CAD software used by 3D printers. A good STL file is necessary for a 3D printed object to be made.

An STL file describes an unstructured, raw triangulated version of the object. What is triangulation? Triangulation is the division of an object into triangles. By presenting an object in this way, an STL file can be used by a 3D printer to produce the object layer by layer. This works even for complex objects with odd or even rounded shapes.

How do you make one of these vital STL files?

Creating 3d Files For Printing

To start with, there are several different types of software you can use. Here are two that we recommend:

Fusion 360 – This software is a cloud-based cloud-based parametric solid-modeler. It offers a number of modes, each with their own uses which are included in parenthesis: Model (Parametric Solid Modeling), Patch (Surface Modeling), Render (Real-time Ray Tracing), Animation (Timeline & Animations), Simulation (Validate & Optimize Designs), and CAM (Manufacturing).

SolidWorks – This software functions much the same as Fusion 360 in practical terms, providing you with the ability to work from idea to prototype model all in the same program. SolidWorks is not cloud-based.

Much like the Microsoft Office suite and the Google G Suite, these two sets of software offer very similar results but there is a substantial amount of difference in interface.

In terms of UI, Fusion 360 is more sleek, with a single command capable of multiple functions depending on user need. However, Solidworks is more customizable for those who like to make use of hotkeys to save time. The interface is generally more customizable, with a light, medium, and dark option.

Fusion 360 feels easier to use for many than SolidWorks. It seems designed for quicker work all around, with a press/pull function and the ability to constrain planes to certain dimensions. However, sketching is thought to be easier in SolidWorks, and both programs are heavily sketch-based.

The biggest differences between the two are the use of the cloud and their available OS. Fusion 360 saves your work to a cloud, allowing for easy sharing between teams and workspaces. It can also be used on any OS. Undertale collectors edition soundtrack. Neither of these is the case with SolidWorks.

Create 3d Print Files

Both Fusion 360 and SolidWorks see a lot of use in academic and business environments. If you want a simple introduction to the principles you see in modeling for 3D printing, however, try TinkerCad, which comes from Autodesk, the makers of Fusion 360. TinkerCad is free and simple to use. A quick glance through their gallery reveals all sorts of designs. It is a great introduction for anyone who wants to learn how to do 3D design, regardless of age.

Call of duty modern warfare beta blizzard. At Jawstec, we can help you use this software to create STL files that can bring your idea to life. Whether you have an STL file ready to go or just have an idea, we know how to use 3D printing technology to the high-quality products that you need. Contact us today to get a 3D design quote so we can start taking your ideas from dreams into reality.